| Sign In | Join Free | My himfr.com |

|

- Home

-

Products

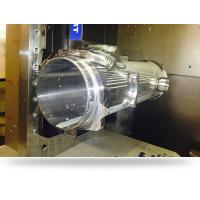

- Metal CNC Machining(15)

- 5 Axis CNC Machining(25)

- CNC Parts Machining(30)

- 316 SS Plate(51)

- 304 SS Plate(53)

- Custom Machining Service(38)

- Large Machining(24)

- Large CNC Milling(15)

- CNC Lathing Parts(15)

- Precision Machining Parts(21)

- Complex Machining(23)

- Metal Stamping Parts(11)

- Plastic Injection Mould(1)

- Large Shaft Machining(11)

- Custom Flange Pipe(19)

- About Us

- Quality Control

- Contact Us

- Get Quotations